10.12.2025

Studying Shunt Currents in a Water Electrolysis System: A Partnership Between Stargate Hydrogen, ABB and LUT – PART 2

Takeaways

- Shunt currents significantly affect the efficiency of alkaline water electrolysis systems, especially when stacks are connected in series.

- Results from this phase of the study provide practical insights into hydrogen production using different voltages and how shunt currents form, behave, and impact current efficiency.

- The team found that while series connections offer tangible benefits for reducing current load on power electronics, they also introduce new challenges, especially at low operating currents.

Moving from theory to measuring shunt currents in a water electrolysis system

In PART 1, we outlined the challenges of shunt currents in alkaline water electrolysis systems and how they affect efficiency when increasing system voltage by connecting electrolyser stacks in series. Now, the project by Stargate Hydrogen, ABB, and LUT University has entered its first experimental phase with real data from a scaled testbed.

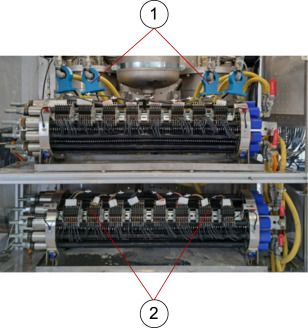

To better understand how shunt currents behave and how to reduce their impact, the research team developed a test configuration using two stacks built by Stargate Hydrogen. This setup, while smaller than industrial-scale systems, mirrors the operational parameters of full-size plants, allowing for precise control and meaningful analysis.

To learn more about the project setup and its objectives, read Part 1 here

The Two-Stack Test Setup: Small Scale, Big Value

The two-stack configuration was chosen for its balance between complexity and manageability. The researchers chose a serial connection of shorter stacks to avoid severe stray current problems, which would occur if voltage elevation were implemented by building a single water electrolysis stack with an extended number of cells connected in series.

Each stack in the system was a purpose-built version of Stargate Hydrogen's industrial alkaline electrolyser design, scaled to maintain realistic operating characteristics. The stacks were connected in series to achieve a portion of the final target voltage (1000 V) under medium-voltage conditions.

Test Setup Details:

- Stacks: 2 Stargate Hydrogen custom-built water electrolysis alkaline stacks (48 cells each)

- System Voltage: Approximately 200–300 V during operation

- Power Supply: ABB’s ACS880 power rectifier

- Nominal Current: 60 A

- Instrumentation: Individual cell voltage probes, current sensors, and grounded piping

- Hoses: Electrically insulating electrolyte hoses connected stacks to manifolds

- Piping: Grounded stainless-steel piping linked manifolds to gas separation tanks

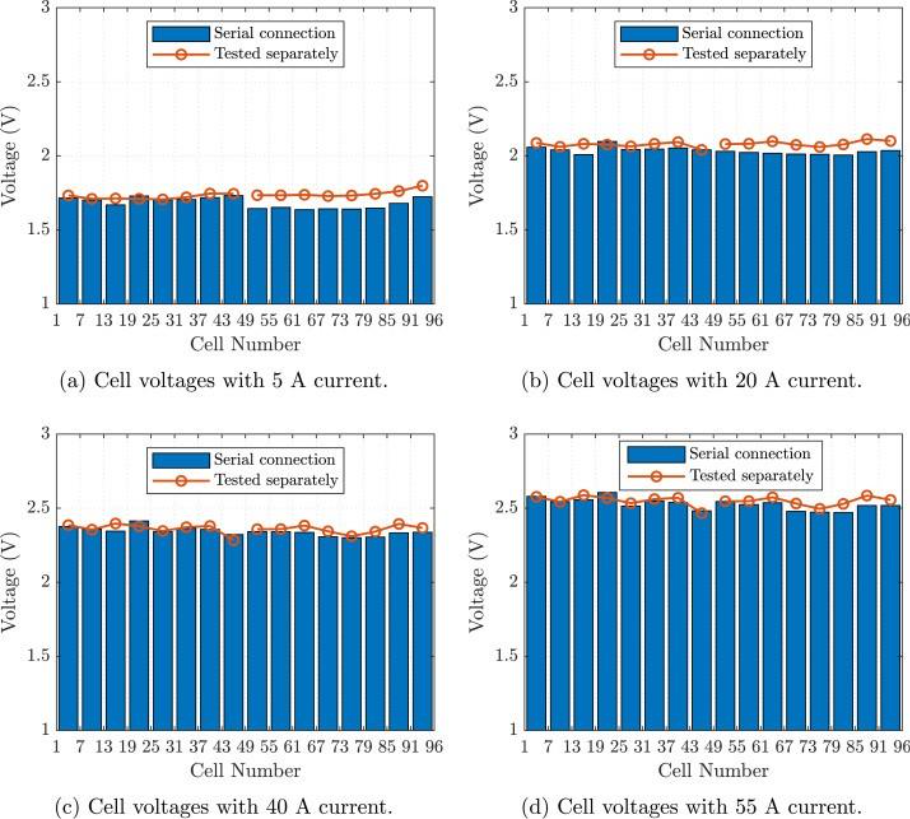

This setup allowed the team to monitor the exact voltage of each cell in both stacks and calculate shunt current losses in different components of the system. Grounding schemes and hose insulation were critical in limiting parasitic current paths, a key focus of the study.

Tracking Shunt Currents in Water Electrolyser Systems:

What Was Measured and Why It Matters

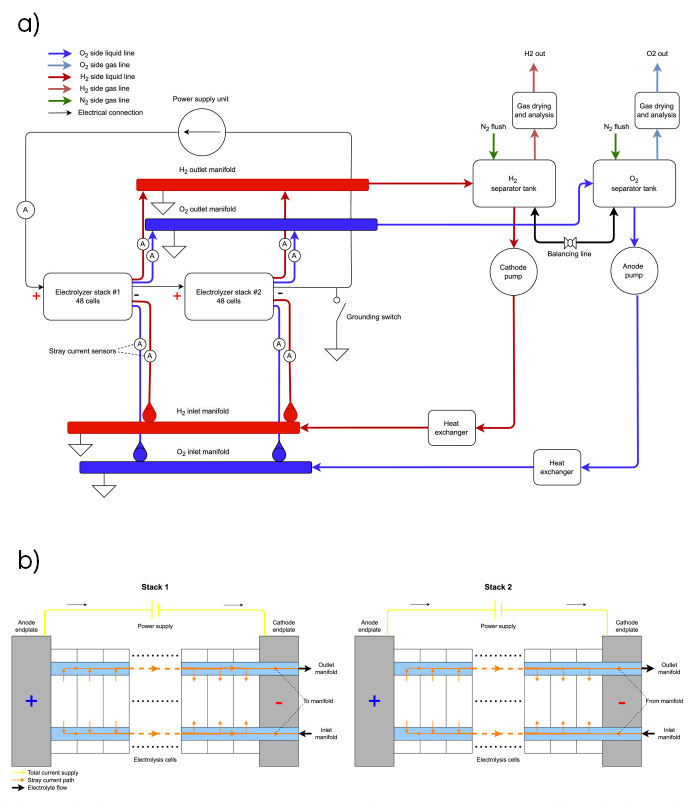

The researchers concentrated on measuring how much current was bypassing the intended water electrolysis path, either through piping, manifold connections, or external grounding loops. These shunt currents lead to energy loss and reduce current efficiency.

(a) Simplified piping and instrumentation diagram of the AWE system, illustrating external shunt current paths to and from the stacks.

(b) Simplified illustration of internal shunt current paths. Each stack consists of 48 cells; the middle sections are omitted and indicated with dotted lines. Due to the higher potential of stack 1, shunt currents flow outward toward the manifolds, whereas in stack 2, they flow inwards from the manifolds.

Key Measurements:

- Cell Voltage Distribution: Ensures even power delivery across the stack

- Current Efficiency: Compares actual hydrogen output to theoretical yield

- Shunt Current Flow: Monitored via sensors at key leak-prone points

- System Resistance: Evaluated for stack, hose, and manifold sections

- Ground Current Paths: Assessed using differential current monitoring

Understanding where and how current escapes help engineers design better stack connections, select materials more effectively, and build water electrolysis systems that are not only more efficient but also safer and more cost-effective.

Results From the Two-Stack Study

Initial findings from the 2-stack phase of the study were presented at the International Conference on Electrolysis (ICE 2025) in Freiburg, Germany, and were subsequently published in the Journal of Power Sources.

Key Findings:

- Operational Feasibility: Serial connection was technically successful. Both stacks operated reliably, with only minor reductions in efficiency.

- High Current Efficiency: Individual stacks achieved >95% current efficiency. When connected in series, the water electrolysis system maintained high efficiency, with specific energy consumption (SEC) increasing by less than 5% when the current exceeded 50% of the nominal load.

- Efficiency Drops at Low Currents: At low power levels, external shunt currents accounted for up to 30% of the total supply current, resulting in efficiency losses of 10%–20% compared to single-stack operation.

- Effect of Grounding: Grounding the second stack increased shunt current levels due to higher potential gradients between the stacks and ground.

- Electrolyte Flow Rate Effects: Higher electrolyte flow improved gas removal and slightly reduced cell voltages by around 1%, but this also increased shunt current leakage through outlet hoses.

- Model Accuracy: Theoretical models underestimated actual shunt currents, likely because gas removal was more effective in practice than assumed, leading to higher conductive paths than predicted.

These results highlight the delicate balance between system design and operational performance in water electrolysis systems. The team found that while series connections offer tangible benefits for reducing current load on power electronics, they also introduce new challenges, especially at low operating currents.

Design Recommendations for a water electrolyser system:

- Connecting relatively short stacks in series can mitigate shunt currents in elevated-voltage alkaline water electrolysis systems.

- Optimize hose routing and stack spacing to minimise conductivity paths for shunt currents.

- Use controlled operating temperatures to reduce voltage losses while maintaining durability.

- Adjust electrolyte flow rate to balance gas removal efficiency and shunt current control.

📘 You can read the full publication here: Journal of Power Sources

These findings confirm that multi-stack systems connected in series are a viable path forward, especially when design strategies actively mitigate the formation of shunt currents. The results of this study now serve as a blueprint for scaling to more complex, higher-voltage systems, which will be the focus of the upcoming experiment with all 10 stacks installed.

The Road Ahead: Scaling Up to 10 water electrolysis Stacks

The current findings lay out the groundwork for the next stage of the study, which will expand the setup to a full 10-stack series configuration. This system will operate at 1000 V and 60 A.

In this next phase, the team will continue examining how shunt currents behave when even more interconnections, longer fluid paths, and higher voltages are introduced. The influence of scaling system-level resistance, current leakage, and efficiency will be critical in determining whether serial stack configurations can be reliably used in commercial hydrogen production systems.

Want to learn more about how Stargate Hydrogen is shaping the future of water electrolysis systems? Visit stargatehydrogen.com and explore our blog, products, and ongoing research. Discover how our technologies are helping to enable the industry of tomorrow.