Alkaline electrolysis is the most robust and proven form of electrolysis to produce hydrogen from water. Despite the proven technology, no ready-made solution for large-scale industrial applications exists. The need for such solutions is emerging from the rapid roll-out of electrolysers deployment in novel domains.

At Stargate, we strongly believe that alkaline electrolysis technology has a lot of untapped potential left, and we are actively pursuing ways to improve the efficiency and lower the cost of alkaline cells, stacks and systems.

The current state of alkaline electrolysers

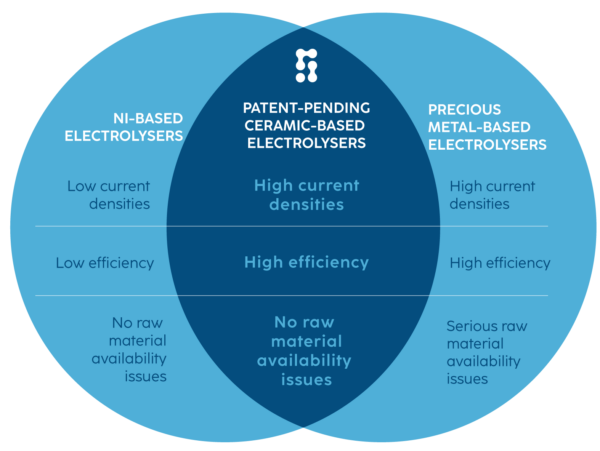

Although alkaline electrolysis technology is often described as being free of platinum group metals, the fact is that a large fraction of alkaline electrolysers are still utilising electrodes made of ruthenium and iridium which are some of the rarest elements in Earth’s crust.

While alkaline electrolysers boast high current densities and high efficiency, their wider adoption is hindered by raw material availability issues. Nickel-based alkaline electrolysers do not face raw material availability issues, but suffer from lower current densities and lower efficiencies.

Beyond the State-of-the-Art in Alkaline Electrolysis

At Stargate, we build upon the best aspects of proven alkaline electrolysis technology and complement it with breakthrough materials. This results in a completely new class of electrolysers: ceramics-based alkaline electrolysers, that have high current densities, and high efficiencies, yet contain no precious metals. This results in significantly lower hydrogen production costs and makes the electrolysers affordable for the end-users.

Our unique electrode technology relies heavily on scientific research

100% owner of the intellectual property

Fully equipped R&D Centre

Decades of combined experience

Authored 100+ scientific publications

Prior experience from renowned companies

We are open to collaborations in both demonstration and research projects in various fields.

Contact us for more insights.