Electrolysers

Decarbonisation with Green Hydrogen

By significantly reducing the cost of green hydrogen production through our innovative technologies and efficient processes, we play a crucial role in expediting the decarbonization of the toughest industries where we find the biggest CO2 emitters, such as steelmaking, fertilizers, and chemicals.

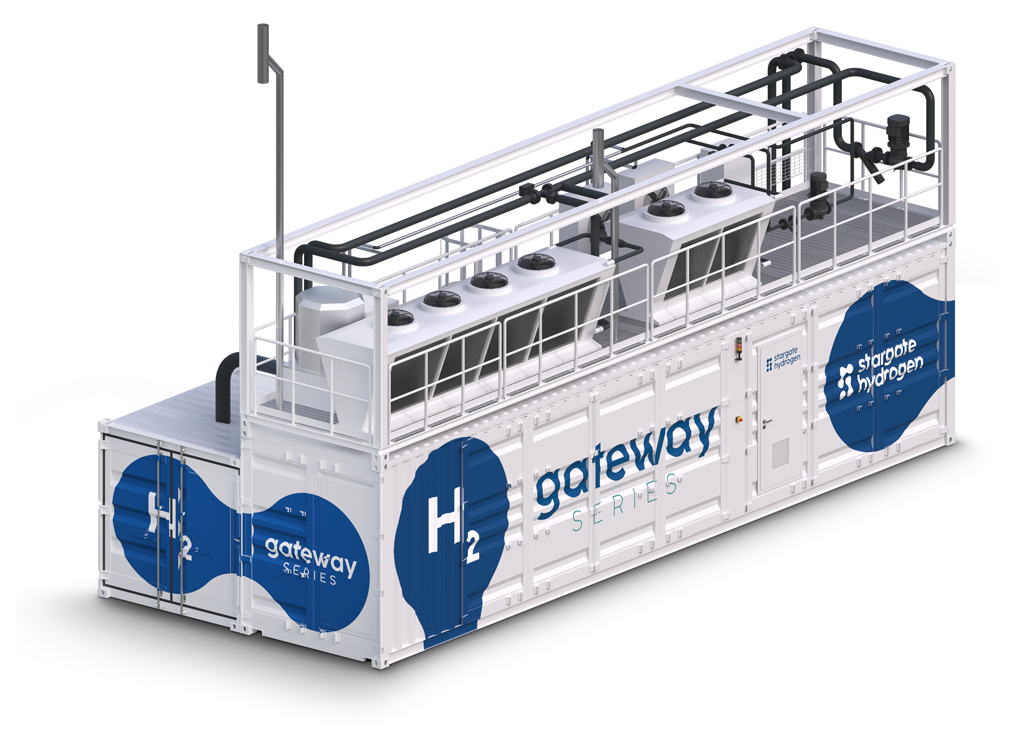

Gateway Electrolysers

Specifications

Modular turn-key systems

1 – 10 MW

Leading warranty on the market

Dynamic operation for RES

Gateway electrolysers are containerised turn-key green hydrogen production systems using alkaline technology, that has a proven track record of long operational lifespans, which makes them a reliable choice for continuous hydrogen production.

This durability minimizes downtime and maintenance costs, contributing to the economic feasibility of green hydrogen. The technology has been validated by several institutions including the Fraunhofer Society.

Each 40ft container consumes 1 MW of electricity and produces 200 Nm³/h of hydrogen, pressurised to 30 bar as output. The systems can be ordered with a 12-month lead time and come with an industry-leading performance guarantee. The electrolysers are highly suitable for a wide range of applications such as chemical feedstock, process heat, blending, transport fuel and energy storage.

Stargate electrolysers are highly suitable for a wide range of applications.

Chemical feedstock

Process heat

Blending

Transport fuel

Energy storage

Our state-of-the-art electrolysis systems harness alkaline technology to deliver hydrogen at the ideal pressure, effectively revolutionizing energy efficiency while maintaining low costs. Our groundbreaking technology is entirely free from precious metals such as iridium and ruthenium, making it not only eco-friendly but also economically sustainable.

That sets our electrolysis systems apart is their inherent scalability, allowing businesses to seamlessly adapt and expand their hydrogen production capabilities according to their evolving needs. By eliminating the need for costly precious metals and enabling high-pressure hydrogen production, our innovative approach to electrolysis paves the way for a more sustainable and cost-effective future.