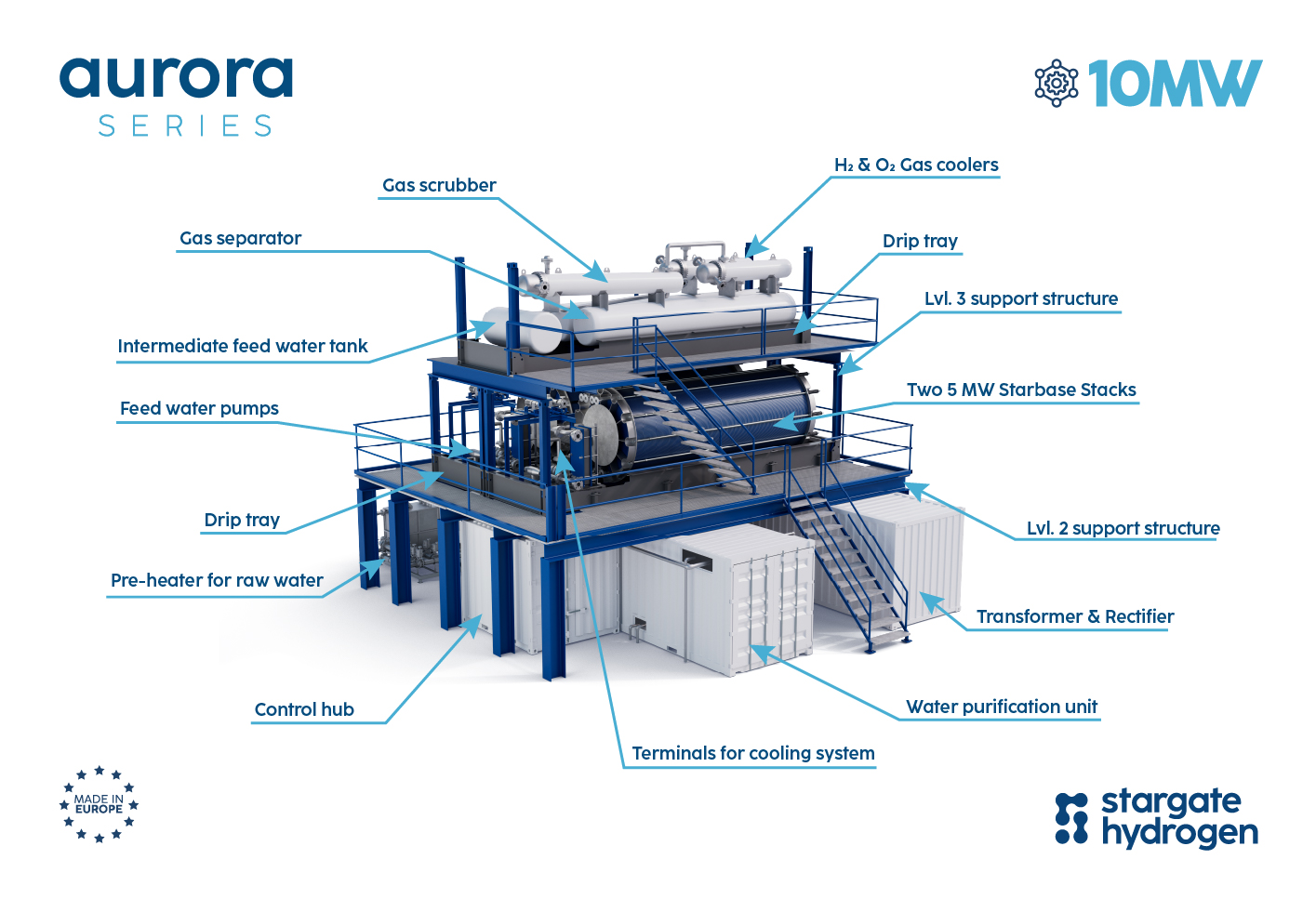

10 MW Electrolyser System

for heavy industries

By significantly reducing the cost of green hydrogen production through our innovative technologies and efficient processes, we play a crucial role in expediting the decarbonization of the toughest industries where we find the biggest CO2 emitters, such as steelmaking, fertilizers, and chemicals.

10MW Electrolyser Systems for hydrogen production

Lowest m²/MW ratio

Outdoor solution, no building needed

Clear documentation and support

Dynamic operation for renewables

The Aurora Electrolyser system is Stargate Hydrogen’s biggest module.

Based on proven alkaline technology, it combines reliability with innovation to deliver a pressurized, compact system offering the highest MW/m² ratio in the market. We know that space is expensive, that is why the Aurora Systems has only a 14.4m²/MW footprint.

It comes with clear documentation, full engineering support, and maintenance training delivered by experienced technicians, Aurora simplifies ownership while maximizing uptime and efficiency.

Pre-manufactured for cost saving, highest quality and easy installation on site. The Aurora is an outdoor-ready solution that requires no buildings, engineered to withstand from the freezing to extreme heat temperatures.

Take the next step toward a cleaner future with Aurora Electrolyser System.

Wide range of applications

RES Projects

Transport Fuel

Fertiliser Industry

Steel Factory

Oil Refinery

Designed and made in Europe, Aurora arrives as a complete, pre-manufactured solution minimizing installation costs and accelerating time to production. Its rugged engineering ensures consistent performance in any climate, from the freezing cold of the Nordic regions to the scorching heat of desert environments, eliminating the need for additional building infrastructure.

Aurora is a scalable, future-proof hydrogen platform. Its modular design allows rapid expansion, while compatibility with renewable energy makes it the ideal choice for industries committed to decarbonization.